Modbus is a communication protocol that is widely used in industrial automation systems. It was developed by Modicon (now Schneider Electric) in 1979 and is used to connect different devices and control systems in a network. Modbus is based on a master-slave architecture, where one device acts as the master and the other devices act as slaves. The master device sends requests to the slaves and the slaves respond with the requested information.

ModBerry is a device that uses the Modbus protocol to communicate with other devices in a network. It is a small computer that is based on the Raspberry Pi platform and it is designed to be used in industrial automation systems. The ModBerry device can be used as a master or a slave in a Modbus network and it can be used to connect different devices such as sensors, actuators, and controllers.

ModBerry advantages in the IoT market

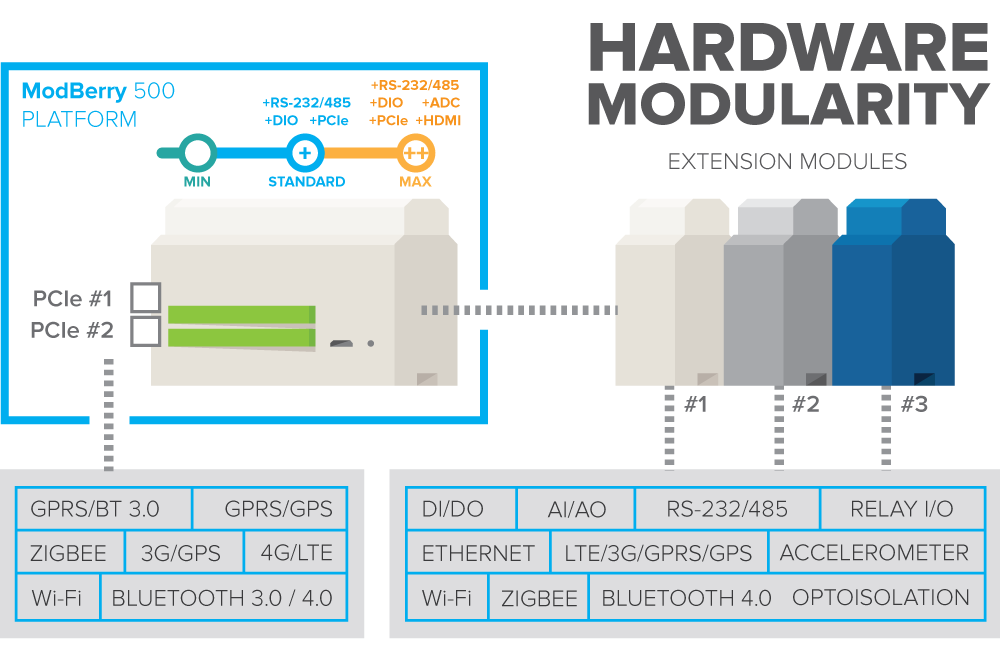

One of the main advantages of using ModBerry is that it is a low-cost solution for industrial automation systems. It is also easy to use and it can be programmed using different languages such as Python, C++, and Java. Additionally, the ModBerry device is small and compact, which makes it easy to install in different environments. It also has a wide range of input and output options, such as digital inputs, digital outputs, analog inputs, and analog outputs, which makes it suitable for a variety of applications.

ModBerry can be used in various industrial applications such as building automation, energy management, and process control. For example, it can be used to monitor and control the temperature, humidity, and lighting in a building. In energy management, it can be used to monitor and control the consumption of electricity, gas, and water. In process control, it can be used to monitor and control the production process in a factory.

Another advantage of ModBerry is its flexibility and scalability. It can be easily integrated with other systems and devices, such as SCADA systems, PLCs, and IoT devices. This allows for a seamless integration of different systems and devices in a single network, which improves efficiency and reduces the complexity of the system.

ModBerry as a low-cost Modbus controller

In conclusion, Modbus is a widely used communication protocol in industrial automation systems and ModBerry is a low-cost, easy-to-use device that utilizes the Modbus protocol. It offers a wide range of input and output options and can be used in various industrial applications. Its flexibility and scalability make it a great solution for integrating different systems and devices in a single network.

Order now: https://www.industrial-devices.com/industrial-computers/1-46-mod-500.html